The Ultimate Guide to Fabric Cutting Machines and Pattern Design Software

Introduction

Let’s be honest — sewing isn’t what it used to be. Gone are the days of hand-drawn patterns and scissors. The modern textile world now thrives on automation, precision, and speed. That’s where Fabric cutting machine and pattern design software come in. Whether you’re a hobbyist, a fashion entrepreneur, or running a full-blown production unit, these two tools can make or break your productivity.

In this guide, we’ll dive deep into what these machines and software do, how they work together, and how they can transform your textile game.

What Is a Fabric Cutting Machine?

A fabric cutting machine is a device designed to cut fabrics with high precision, minimal waste, and in less time than manual methods.

Types of Fabric Cutting Machines

There are several types of machines available depending on your need:

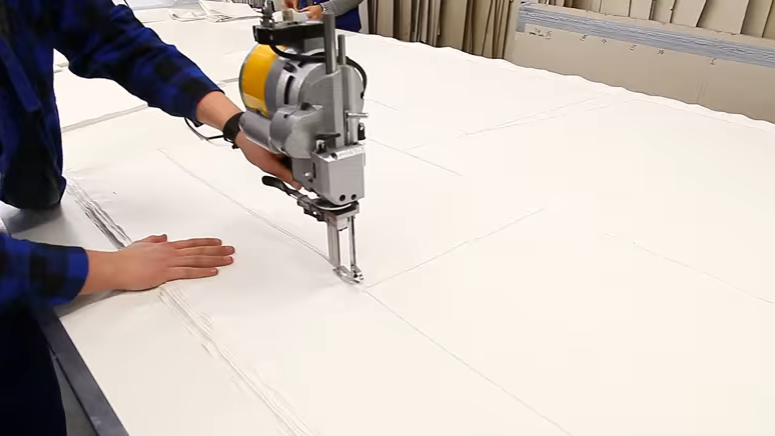

- Manual Fabric Cutters: Hand-operated tools like rotary cutters or handheld electric cutters.

- Semi-Automatic Cutters: These include electric cutters with guides.

- Automatic and CNC Cutters: These use computer controls for high-precision bulk cutting.

Benefits of Using Fabric Cutting Machines

- Precision: Say goodbye to jagged lines and human error.

- Efficiency: Cuts down labor time by more than half.

- Consistency: Ensures every piece is exactly the same.

- Scalability: Perfect for both small batches and mass production.

What Is Pattern Design Software?

Pattern design software allows designers to digitally create and modify garment patterns on a computer. Think of it as Photoshop but for clothes!

Features of Pattern Design Software

- CAD Tools: Allows easy drafting and grading.

- Auto Nesting: Automatically arranges patterns for optimal fabric usage.

- 3D Simulation: Preview how the garment fits and flows.

Advantages of Digital Pattern Design

- Time-saving: Faster than drawing patterns manually.

- More Accurate: Reduces costly errors.

- Easy Edits: Modify designs on the fly.

- Integration: Pairs easily with cutting machines.

How Fabric Cutting Machines and Pattern Design Software Work Together

Here’s the magic: once you’ve designed your pattern on the software, it can be sent directly to the cutting machine. The cutter reads the digital file and slices the fabric according to the exact specifications.

This seamless integration creates a fully automated workflow, minimizing human touchpoints and maximizing efficiency.

Types of Fabric Cutting Machines Explained

Manual Fabric Cutters

Perfect for beginners and small jobs. Think rotary cutters, scissors, or manual straight knives. Inexpensive, but time-consuming.

Electric Fabric Cutters

These are handheld and plug-powered. Faster than manual options and great for layered fabrics.

Computerized or CNC Fabric Cutters

These beasts are the heart of modern garment factories. Just load your pattern, feed in your fabric, and let it do the rest. Some even come with laser-guided systems!

Popular Brands of Fabric Cutting Machines

A few brands have made a name for themselves in the industry:

- Gerber

- Brother

- Cricut

- Juki

- Eastman

Each has its own strengths depending on whether you’re cutting vinyl, cotton, denim, or leather.

Choosing the Right Fabric Cutting Machine

For Small Businesses

If you’re starting small or working from home, a compact electric cutter or a Cricut machine is a smart choice. They’re affordable, portable, and get the job done.

For Large-Scale Production

Big operations need big power. CNC machines with multi-layer cutting capabilities and automation features are your go-to.

Key Features to Look for in Fabric Cutting Machines

- Cutting Speed: Faster is better, especially in mass production.

- Material Compatibility: Can it handle different types of fabrics?

- Ease of Use: Look for intuitive interfaces.

- Maintenance Requirements: Low maintenance = less downtime.

- Software Integration: Does it support pattern design file formats?

Understanding Pattern Design Software

2D vs 3D Pattern Design

- 2D Software: Used for flat pattern creation.

- 3D Software: Simulates the look and feel of a finished garment on a digital avatar.

3D is becoming the norm for fashion design, helping brands preview collections before production.

Auto Nesting and Optimization

This function helps you automatically place your patterns on the fabric layout to reduce waste. It’s eco-friendly and budget-friendly.

Top Pattern Design Software Options

Here are some top dogs in the pattern software game:

- Gerber AccuMark

- CLO 3D

- TUKAcad

- Optitex

- Lectra

Each offers a suite of tools from basic drafting to 3D simulation and fabric behavior analysis.

Integrating Fabric Cutting with Pattern Software

It’s as simple as saving your file in the correct format. Most high-end cutting machines accept formats like DXF, HPGL, or native CAD formats. With a Wi-Fi-enabled system, the workflow becomes wireless and lightning fast.

Industry Applications

Fashion Industry

From haute couture to ready-to-wear, these tools streamline everything — sampling, pattern grading, production, and more.

Upholstery and Furniture

Precision-cut upholstery means less material waste and cleaner designs.

Automotive Sector

Car interiors, airbags, and seat covers are all cut with automated fabric cutters and guided by precision software.

Industrial Textiles

Think parachutes, sails, and protective gear — high-performance cutting and designing are essential here.

Cost and ROI Considerations

- Initial Cost: Fabric cutting machines can range from $200 (manual) to $50,000+ (industrial CNC).

- Software Licenses: Varies from $50/month to $5,000/year depending on features.

- ROI: Faster turnaround, less fabric waste, and fewer errors translate to quick payback, often within 1–2 years.

Challenges and Common Mistakes

- Improper Calibration: Can ruin your fabric.

- Wrong Software Integration: Make sure your machine can read the file format.

- Neglecting Maintenance: Always clean and calibrate.

Future of Fabric Cutting and Pattern Design Technology

AI-driven auto-nesting, cloud-based collaboration, and real-time 3D visualization are shaping the future. Expect more user-friendly interfaces, mobile support, and sustainable fabric optimization.

Conclusion

So, are you ready to ditch the scissors and sketchpads? Investing in a fabric cutting machine and pattern design software can revolutionize your production. Whether you’re crafting at home or managing an entire fashion line, these tools offer speed, accuracy, and creativity like never before.

From fabric rolls to final cuts, it’s all about working smarter — not harder.

FAQs

1. What’s the best fabric cutting machine for beginners?

The Cricut Maker or Brother ScanNCut is ideal for small-scale, beginner-friendly use.

2. Is pattern design software hard to learn?

Not at all! Most tools come with tutorials, and the interface is often intuitive, especially for users familiar with graphic design tools.

3. Can I use pattern software without a cutting machine?

Yes, pattern design software can be used alone for digital drafting and visualization.

4. Do I need both 2D and 3D software?

Not always. 2D is sufficient for basic designs, but 3D adds a realistic view for better decision-making.

5. How much can I save with automated cutting?

You can reduce fabric waste by up to 15–20% and speed up production by more than 50%.